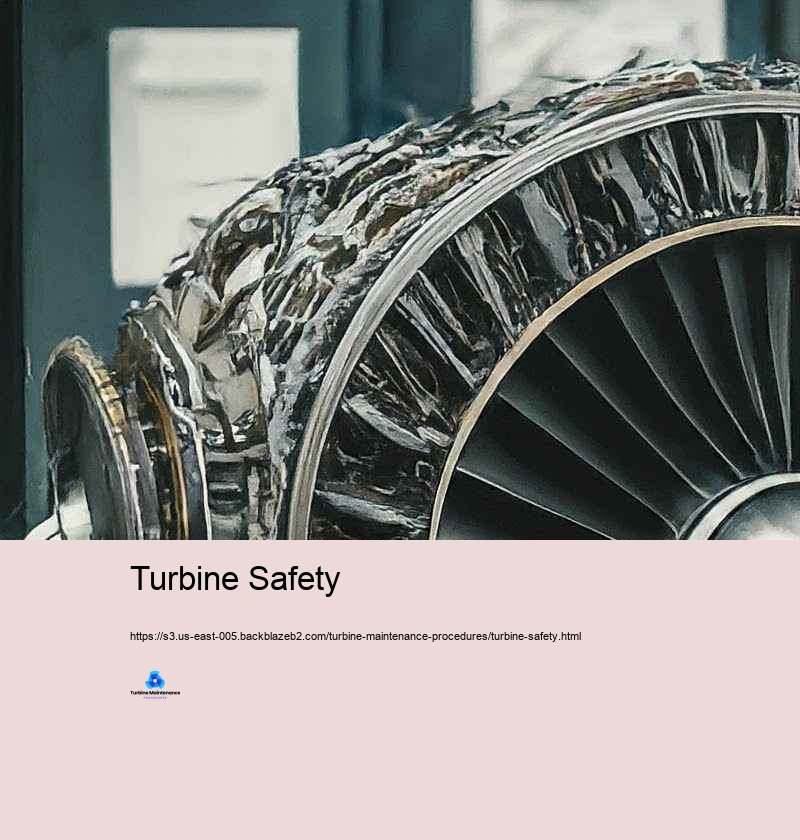

Turbine Safety

Blade Erosion

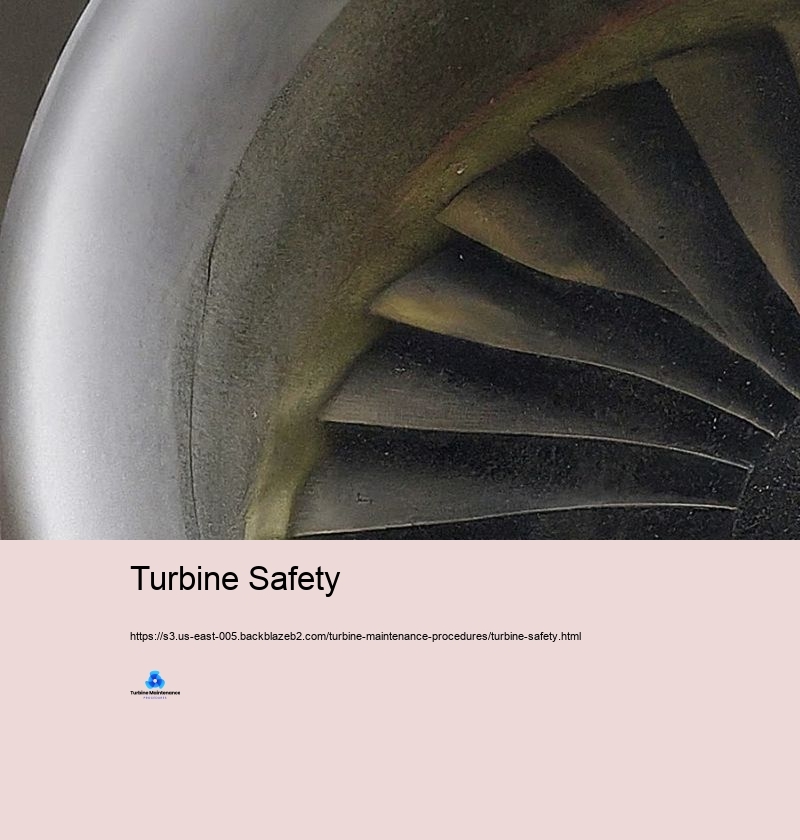

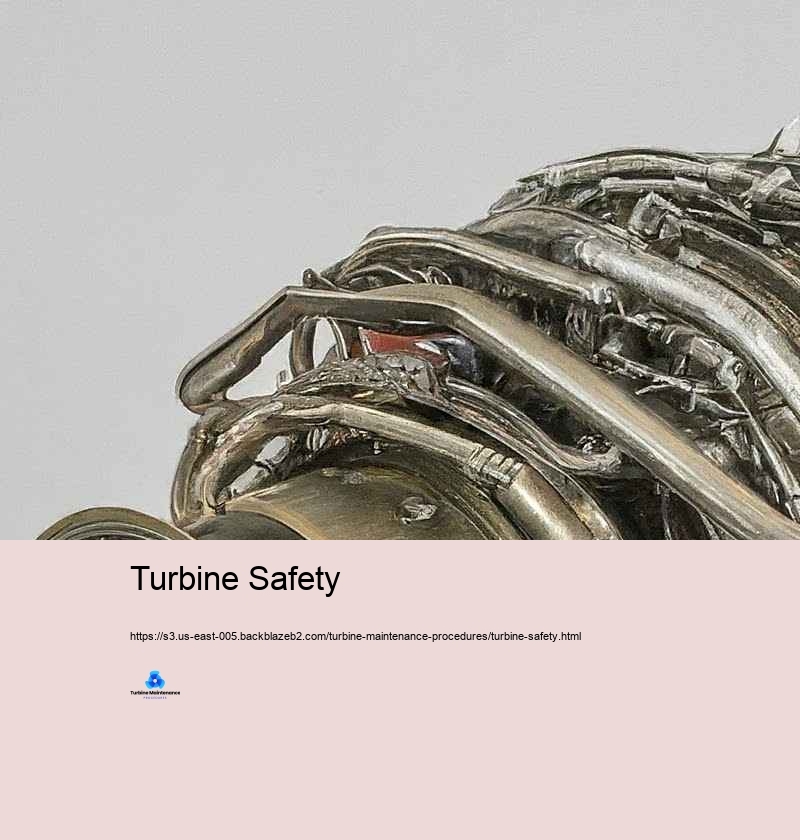

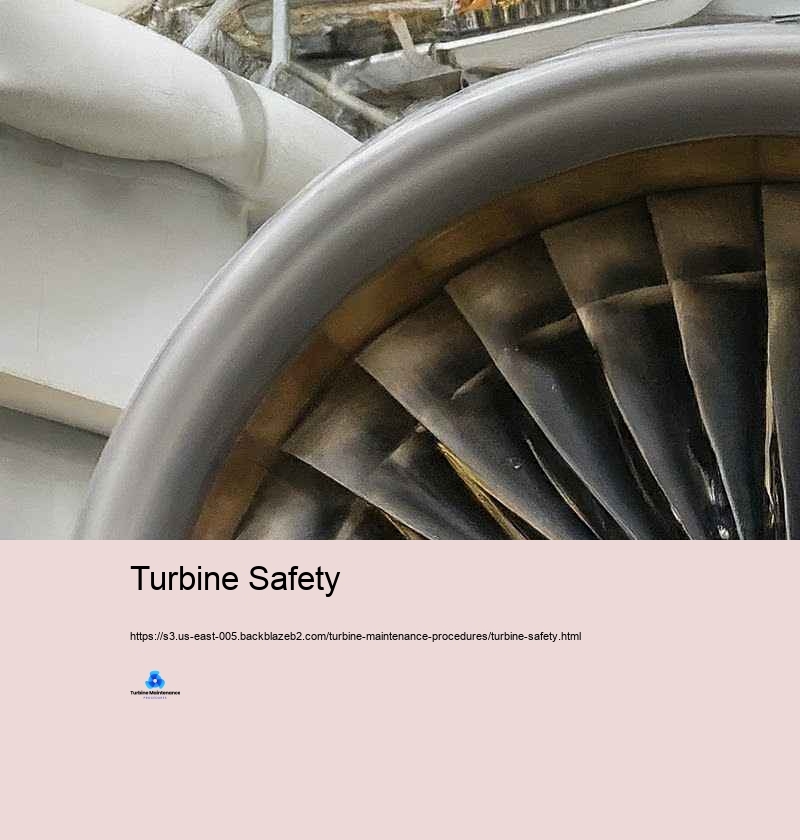

Turbine maintenance is an essential element of power generation, commercial procedures, and various various other applications where generators play a vital responsibility. Right maintenance assurances optimal effectiveness, expands the life expectancy of the devices, and stays clear of expensive break downs. This introductory to turbine maintenance finds the necessary concepts and approaches important for protecting these complicated tools successfully. At its core, turbine maintenance is about preserving the stability and efficiency of the turbine system. Generators, whether vapor, gas, or hydraulic, are innovative items of equipment that transform energy from a liquid (heavy steam, gas, or water) into mechanical energy. The high-speed rotation, extreme temperatures, and anxiety associated with their operation make normal and total maintenance crucial. One of the basic concepts in turbine maintenance is preventive maintenance. This proactive method entails frequently established evaluations, cleansing, and little repair service solutions to avoid substantial failures prior to they happen. Precautionary maintenance typically contains tasks such as lubricating bearings, examining and adjusting clearances, examining blades for wear or damage, and keeping an eye on resonance levels. By attending to little problems early, preventive maintenance can significantly lower the risk of tragic failings and extend the turbine's useful life. Condition-based maintenance is one more vital concept that has obtained importance with the introduction of cutting-edge keeping track of developments. This strategy counts on real-time details from noticing units and watching on systems to determine when maintenance is needed. Specifications such as vibration, temperature degree, pressure, and oil condition are consistently kept an eye on. When these parameters differ typical arrays, it shows possible problems that need rate of interest. Condition-based maintenance enables much more targeted and dependable maintenance tasks, decreasing unneeded downtime and optimizing source appropriation. Anticipating maintenance takes condition-based maintenance an action even more by utilizing information analytics and machine learning algorithms to anticipate when failures are most likely to occur. By taking a look at historical information and present running problems, predictive maintenance systems can projection possible problems before they appear as obvious troubles. This approach permits maintenance teams to plan treatments at the most proper times, minimizing disruption to procedures and optimizing the performance of maintenance tasks. Alignment is a vital technique in turbine maintenance. Appropriate placement of the turbine shaft with the generator or driven devices is crucial for smooth procedure and long life. Imbalance can result in way too much resonance, increased wear of bearings and seals, and reduced performance. Regular placement checks and alterations, frequently using laser positioning tools, are a typical component of turbine maintenance regimens. Balancing is an added important component of turbine maintenance. The high-speed turning of turbine elements means that also little inequalities can cause considerable resonance and put on. Dynamic stabilizing of blades and impellers is carried out to assurance smooth procedure. This procedure includes adding or eliminating small amounts of weight at information indicate acquire optimal balance. Normal resonance analysis aids identify inequality issues early, enabling timely changes. Evaluation and cleaning up of turbine blades are vital maintenance practices. Data Logging and Analysis Blades can deal with different problems such as disintegration, corrosion, fouling, or physical damages. Normal examinations, commonly using borescopes or numerous other non-destructive testing strategies, help identify these issues. Cleansing of blades, which could include chemical cleansing or mechanical methods like grit blasting, aids preserve wind immune efficiency and safeguards against performance destruction. Lubrication checking is an important aspect of turbine maintenance. Turbine Safety Correct lubrication of bearings, gears, and various other relocating parts is essential for decreasing scrubing and use. This involves not only making certain an enough supply of lube nevertheless also checking its high quality. Oil analysis is a regular approach that helps discover impurities, use bits, and adjustments in oil homes that can show developing issues in the turbine system. Seal maintenance is an added important method. Seals stop leak of functioning liquids and lubricating compounds, and their failing can bring about substantial performance losses and prospective safety and safety hazards. Regular assessment and alternative of seals, especially in high-pressure or high-temperature locations, is a common component of turbine maintenance routines. Control system maintenance is considerably essential as generators come to be more automatic and electronically taken care of. This involves regular checks and calibration of sensing units, actuators, and control shutoffs. Software program application updates and cybersecurity steps are in addition crucial elements of modern turbine control system maintenance. Security is vital in all turbine maintenance jobs. Generators involve high powers, extreme temperature level levels, and possibly unsafe items. Strict adherence to safety and security and safety and security procedures, including lockout/tagout procedures, restricted space entry procedures, and correct use specific protective tools (PPE), is essential. Security training and normal refresher courses for maintenance employees are crucial methods in turbine maintenance programs. Paperwork and record-keeping are necessary techniques in turbine maintenance. In-depth logs of all maintenance jobs, including examinations, repair work, and part replacements, give important historic details for pattern examination and future maintenance preparing. Lots of firms presently utilize digital maintenance checking systems (CMMS) to streamline this process and promote info analysis. Training and ability development of maintenance staff members is a persisting method in turbine maintenance. As turbine innovations progress, maintenance techniques and devices in addition breakthrough. Normal training programs ensure that maintenance group are existing with the existing maintenance practices, diagnostic devices, and security procedures. Environmental aspects to think about are happening progressively important in turbine maintenance. This includes proper managing and disposal of hazardous materials like made use of oils and cleaning chemicals. Many maintenance approaches now concentrate on reducing environmental impact while making certain ideal turbine performance. Turbine maintenance is a facility and varied location that includes mechanical, electrical, and significantly, digital experience. The crucial concepts of preventive, condition-based, and preparing for maintenance produce the framework of modern turbine maintenance approaches. Practices such as placing, balancing, blade assessment and cleaning, lubrication administration, and control system maintenance are important for guaranteeing the integrity, performance, and longevity of turbine systems. As turbine innovations stay to progression, maintenance strategies will in addition progress, including brand-new technologies and approaches to satisfy the challenges of keeping these crucial tools in an ever-changing energy landscape.